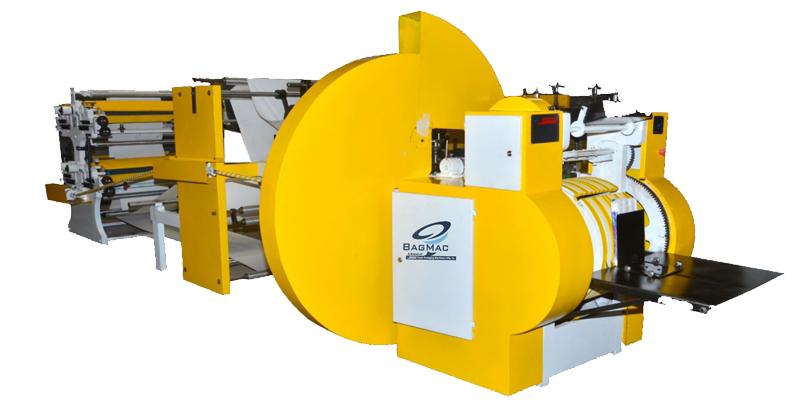

Paper Bag Making Machine

Automatic Roll Feeding Square Bottom Paper Bag Making Machine

Features

Full automatic roll feeding kraft paper bag making machine.

Introduce PLC and In-touch screen human-machine interface centralized control system, with reliable performance, easy for operation and maintenance.

Equipped with Larson & Toubro (L&T) PLC for centralized control system and S ICK photocell for correction, tracking the printed material accurately, minimize the adjustmen t and preset time, increase the production efficiency.

Human oriented security protection, whole housing design, ensure the safety of operator.

Hydraulic Self Loading Reel Stand with one unwinding shaft.

Automatic constant tension control for unwinding, EPC web guider system, motor for material feeding with inverter, minimize the adjustment time for web alignment.

High speed oriented design ensure successful of production: within the suitable paper range, production capacity can reach 100- 120pcs/min, even higher, which increases the unit production capacity and gets higher profit.

Larson & Toubro (L&T) electric system, ensure better stability and reliability; perfect after sale service, trouble free for The machine can be stop automatically once out of material.

Servo motors for main feeding and bag length control Color mark tracking system. On Color error, machine will automatically shut down.

Automatic Oil Lubrication.

Paper impress, bottom folding, gluing and bag formation can be completed automatically.

Side lay working table, easy operation.

Technical Parameter

| MODEL | BAGMAC JUNIOR B |

|---|---|

| Cutting Length(C) | 150-350mm |

| Bag Length(H) | 140-330mm |

| Bag Width(L) | 50-250mm |

| Gusset Depth(S) | 0-80mm |

| Standard Flap(P) | 12-20mm |

| Max.Speed | 250 Pcs/min |

| Paper Thickness | 30-100gsm |

| Paper Roll Width | 120-660mm |

| Max.Roll Diameter | 1000 mm |

| Reel Inner Diameter | 76 mm |

| Printing Color | Double Color |

| Printing Length | 340mm |

| Printing Width | 640mm |

| Overprint Precision | +-0.5mm |

| Thickness of Plate | 2.84m |

| Total Power | 3 H. P |